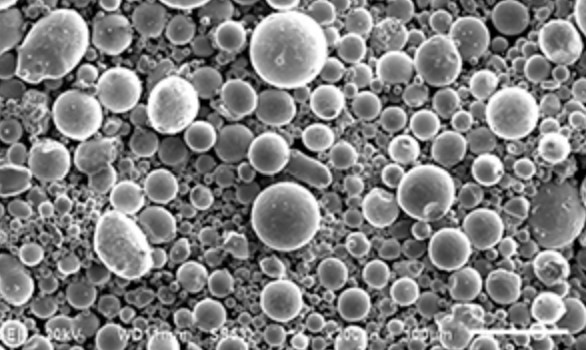

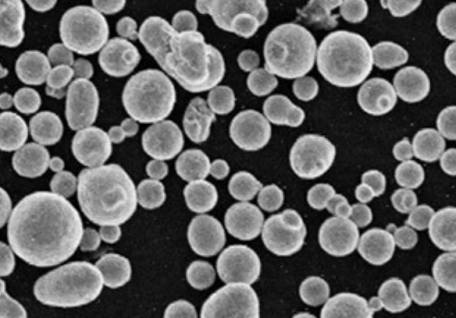

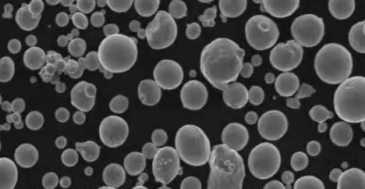

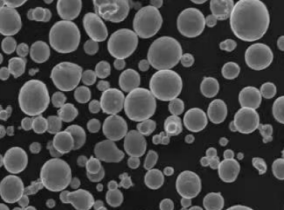

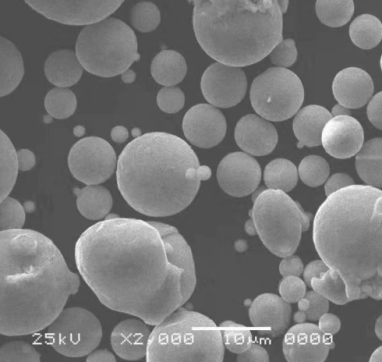

Ti6242 Powder for Additive Manufacturing and PM Applications

1. Introduction: Why Ti6242 Powder Is Gaining Traction in High-Performance Industries Ti6242 is a high-temperature titanium alloy composed primarily of titanium (Ti), aluminum (Al), tin (Sn), zirconium (Zr), and molybdenum (Mo). Its nominal composition is: Element Weight % Ti Balance Al 6 Sn 2 Zr 4 Mo 2 This alloy—often referred to simply as Ti-6Al-2Sn-4Zr-2Mo—is […]

Ti6242 Powder for Additive Manufacturing and PM Applications اقرأ المزيد "