Copper Phosphorus Alloy Powder for Industrial Applications

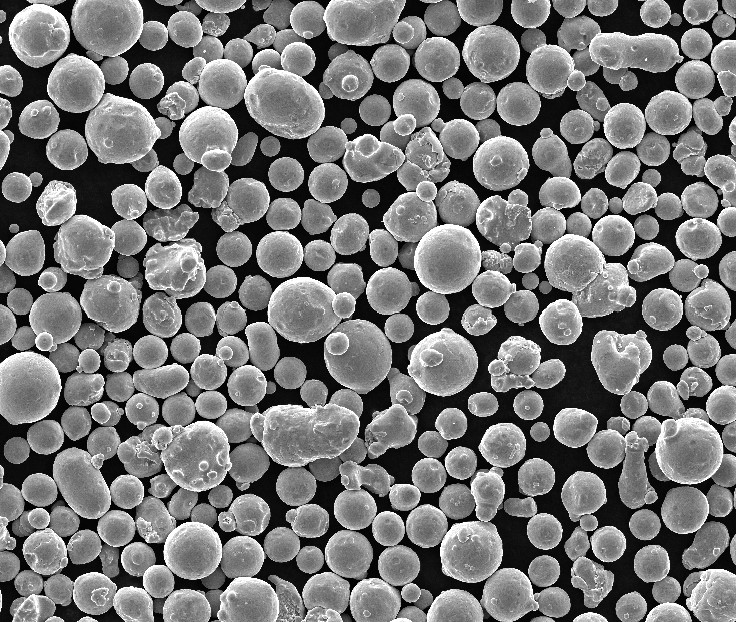

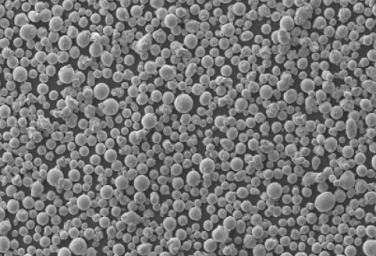

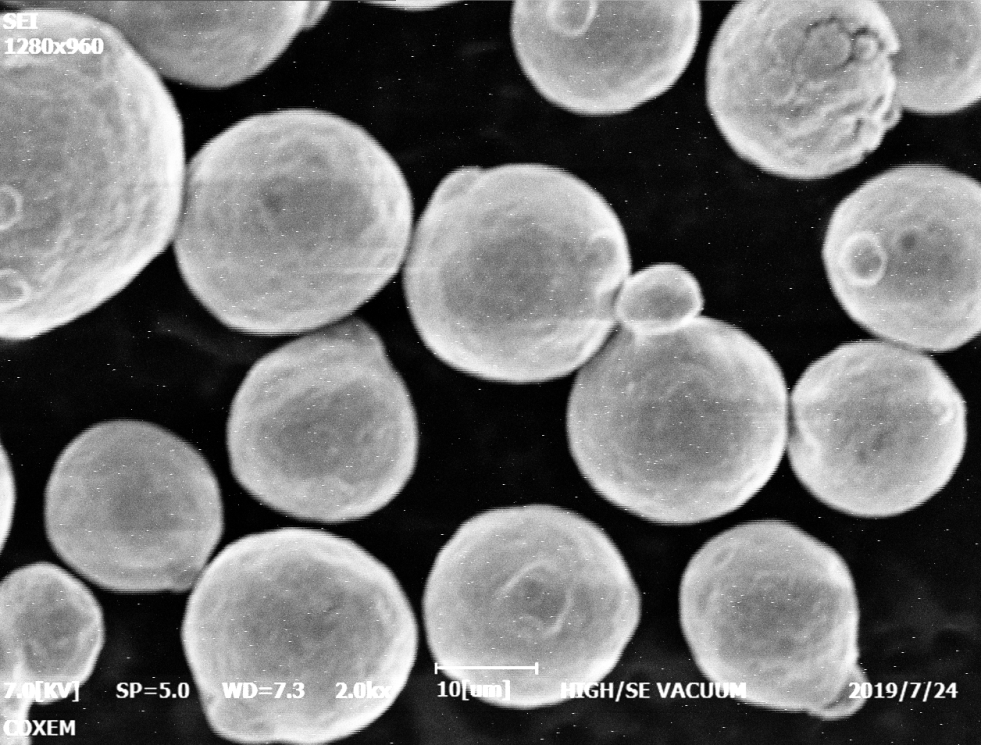

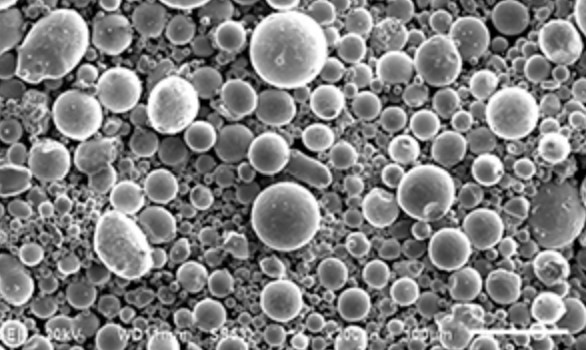

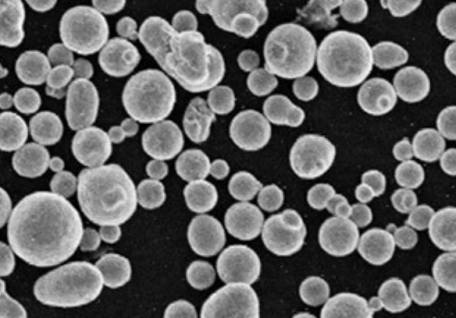

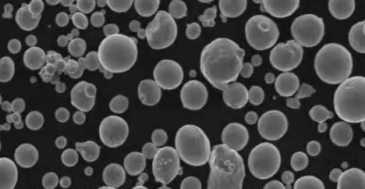

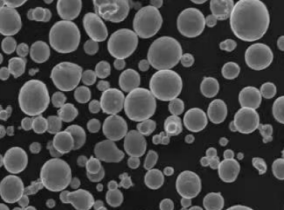

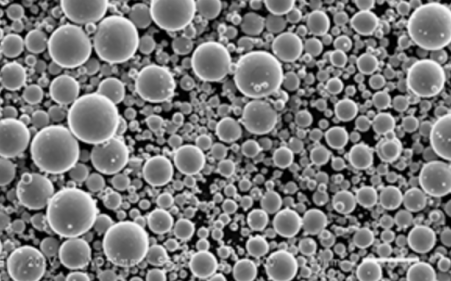

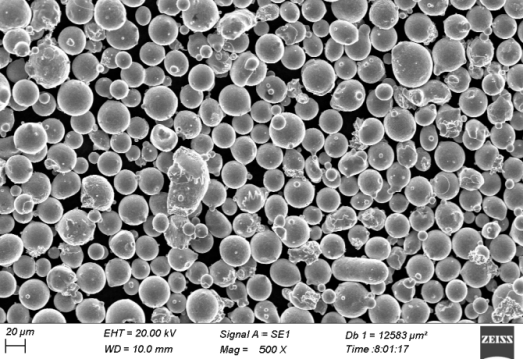

1. Introduction: Importance of Copper Phosphorus Alloy Powder in Industry Copper phosphorus alloy powder, also known as Cu-P alloy powder, plays a vital role in various industrial applications, especially in brazing, powder metallurgy (PM), and the production of sintered components. These powders are designed to enhance the performance, strength, and conductivity of metal parts while […]

Copper Phosphorus Alloy Powder for Industrial Applications اقرأ المزيد "